How Membrane Switches Over Contribute to the Resilience of Electronic Control Panels

Membrane layer buttons play a critical duty in enhancing the sturdiness of electronic control board, mainly with their multi-layered construction which gives efficient defense versus environmental variables such as wetness and dust. This design not only minimizes the threat of circuit damages and rust but also promotes simplicity of upkeep due to its smooth surface. The absence of moving parts substantially decreases the possibility of mechanical failures, making membrane switches ideal for requiring applications. The ramifications of these functions prolong beyond mere defense, increasing questions concerning their more comprehensive impact on functionality and customer experience.

Interpretation of Membrane Layer Switches

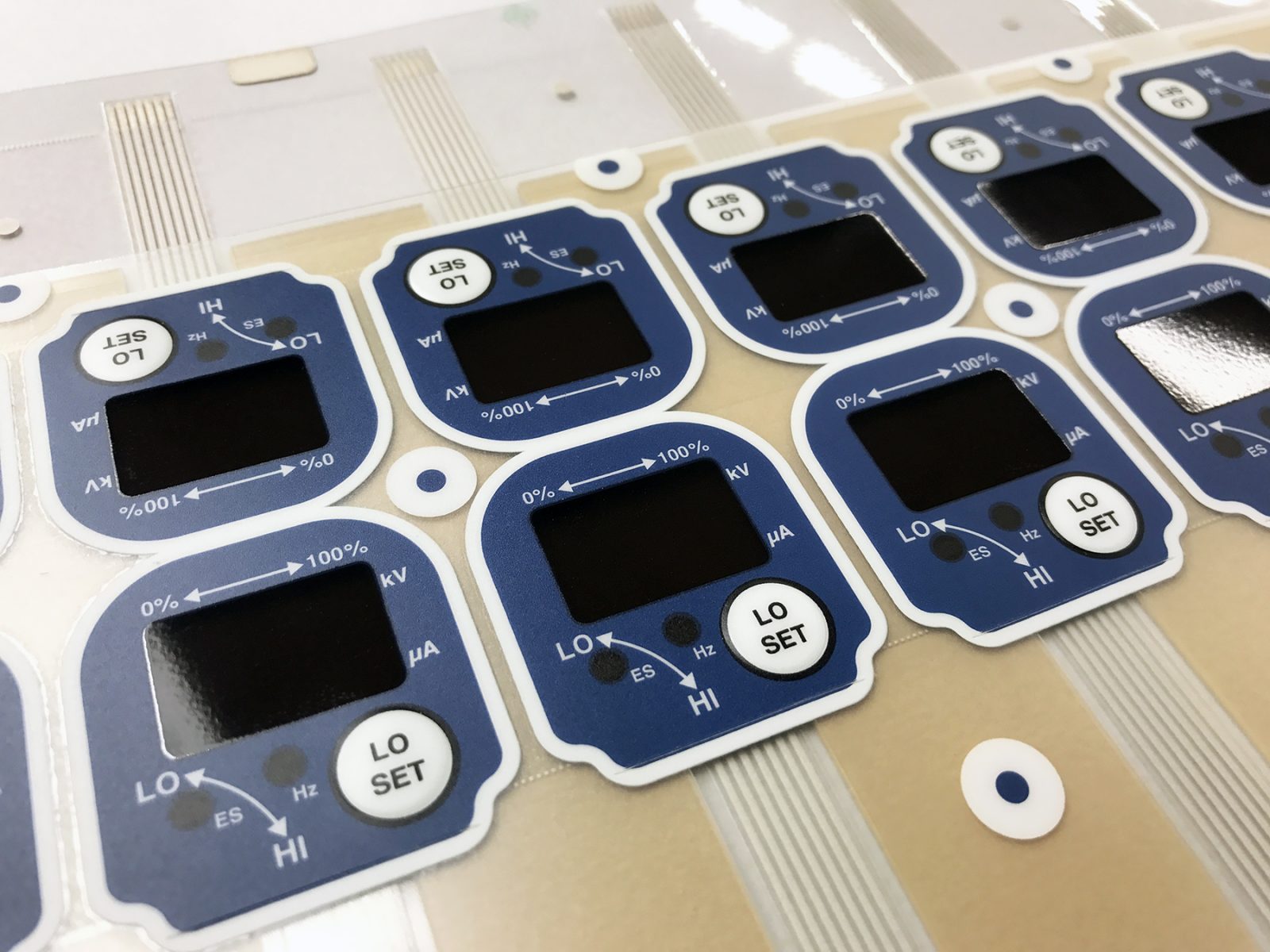

Membrane buttons are developed to be thin and lightweight, making them suitable for applications where area is limited. They can be made in various forms, sizes, and colors, offering adaptability in design that satisfies aesthetic and functional requirements. Furthermore, membrane buttons can incorporate different modern technologies, such as tactile responses and LED indicators, improving user experience.

Because of their building, membrane switches are often resistant to dust, moisture, and basic wear, adding to their longevity in requiring environments. Their smooth style not just facilitates easy cleaning yet additionally minimizes the risk of mechanical failure, making them a preferred selection for manufacturers looking for trusted customer interfaces in their electronic control board.

Defense Against Environmental Elements

The style of membrane changes inherently offers a degree of defense versus various ecological factors, which is essential for preserving functionality in tough conditions - Membrane Switch. These buttons are generally built with layers of adaptable products that secure internal parts from moisture, dust, and contaminants. By encapsulating the wiring, membrane switches decrease the risk of short circuits and rust, which can significantly hinder efficiency

Moreover, using robust adhesives and sealers during production improves their resistance to ecological challenges. Membrane layer buttons can sustain exposure to chemicals and solvents, making them appropriate for markets such as food processing and medical care, where health and cleanliness are paramount. Their seamless surface design also stops the accumulation of dust and bacteria, assisting in much easier cleansing and upkeep.

Temperature level changes are an additional environmental concern, and membrane switches are engineered to work properly throughout a large range of temperature levels (Membrane Switch). This adaptability guarantees that control panels continue to be functional in numerous setups, from commercial environments to consumer electronic devices

Effect On Customer Communication

Individual communication with digital control panels is significantly influenced by the style and performance of membrane buttons. These switches provide a responsive interface that enhances the total customer experience, permitting user-friendly navigation and control. Their receptive nature makes sure that individuals receive immediate comments upon activation, which is vital for tasks requiring precision and effectiveness.

Additionally, the smooth surface area of membrane layer switches assists in easy cleansing and upkeep, promoting user confidence in the integrity of the user interface. This sanitation is particularly vital in environments where hygiene is vital, such as medical or food processing setups. Furthermore, the compact and lightweight design of membrane layer switches over adds to the visual appeal of control panels, urging individual interaction through a modern and streamlined appearance.

In addition, the integration of visual elements, such as printed icons and backlighting, helps customers quickly recognize features, reducing the discovering contour related to brand-new equipment. Therefore, individuals can run tools extra effectively, resulting in boosted performance and fulfillment. In recap, membrane switches play an essential function in boosting user communication by incorporating capability, aesthetics, and convenience of use, eventually bring about boosted operational efficiency.

Design Adaptability and Customization

Style adaptability and customization are necessary facets of membrane switches, allowing makers to customize electronic control panels to specific applications and user needs. This flexibility enables the combination of different layout elements, such as shades, graphics, and structures, which can enhance the visual charm and customer engagement of the control board.

Membrane layer switches can be tailored in shapes and size, fitting a vast array of tools and applications, from commercial machinery to see post customer electronics. This adaptability ensures that suppliers can produce intuitive user interfaces that straighten with customer expectations and operational demands. Furthermore, the capability to incorporate special attributes such as backlighting or responsive feedback further enhances usability, enabling for a much more interactive experience.

Moreover, the production process for membrane changes supports the rapid prototyping address of layouts, making it possible for suppliers to iterate and improve their principles promptly. This ability not just speeds up the development timeline but also ensures that the final item satisfies particular practical and visual requirements.

Cost-Effectiveness and Longevity

Cost-effectiveness and durability are significant benefits of membrane buttons, making them an eye-catching choice for makers and end-users alike. These buttons are generally less costly to produce than typical mechanical buttons, mostly due to their simplified manufacturing procedures and the decreased number of components needed. This cost advantage extends not just to initial manufacturing however also to long-lasting functional expenditures, as membrane buttons often require less upkeep and have a reduced failure rate.

Furthermore, the long life of membrane layer changes adds to their overall worth. Constructed from durable materials, they are resistant to ecological variables such as wetness, dirt, and chemicals, which can cause premature wear in other button types. The absence of moving parts minimizes mechanical failure, permitting membrane switches to preserve performance over expanded periods.

This longevity is specifically advantageous in applications calling for consistent efficiency under requiring conditions, such as medical gadgets and industrial devices. Inevitably, the combination of cost-effectiveness and durability makes membrane layer switches a financially sensible selection for producers, supplying reputable remedies that stand up to the examination of time while maximizing budgetary factors this article to consider.

Verdict

In final thought, membrane switches substantially improve the resilience of digital control panels with their robust building and protective attributes - Membrane Switch. Overall, membrane layer switches over represent a reliable and affordable option for improving the long life and capability of digital control systems.